What Are Climbing Ropes Made Of

How Do Climbing Ropes Work?

Climbing ropes are designed to absorb and dissipate the force generated during a fall, significantly reducing the impact on the climber and anchor system. The elasticity of dynamic ropes, for instance, stretches to absorb the kinetic energy, minimizing the jarring forces on a climber's body. In contrast, static ropes are ideal for applications where minimal stretch is required, such as rappelling, hauling gear, or ascending fixed lines.

How Do Ropes Work When Rock Climbing?

During rock climbing, ropes are an integral part of the belay system. They connect the climber to the belayer and provide a lifeline in case of a fall. The belayer manages the rope through a belay device, allowing slack to be taken in or paid out as needed. If the climber falls, the rope tightens, and the belay device locks to arrest the fall, ensuring the climber's safety.

The Difference Between Static and Dynamic Ropes

Dynamic Ropes

Dynamic ropes are specially designed to stretch under load, which makes them ideal for lead climbing and other scenarios where falls are common. The stretch absorbs the force of a fall, reducing the impact on the climber and the anchor system.

Static Ropes

Static ropes, on the other hand, are designed with minimal stretch and are primarily used for activities like rappelling, rescue operations, and hauling gear. Their rigidity makes them unsuitable for lead climbing as they do not effectively absorb the forces of a fall.

The Manufacturing Process of Climbing Rope

The manufacturing process of climbing ropes is a meticulous and highly specialized operation designed to ensure safety, durability, and performance under extreme conditions. Here is a detailed step-by-step look at how climbing ropes are made:

1. Raw Material Selection

The process begins with selecting high-quality synthetic fibers, typically nylon or polyester. Nylon is favored for dynamic ropes due to its elasticity and ability to absorb shock, while polyester is often used for static ropes because of its lower stretch and resistance to UV degradation. These materials are chosen based on their tensile strength, flexibility, and long-term durability.

2. Fiber Spinning

The raw materials are spun into threads using advanced spinning machines. The threads are treated to improve their strength, elasticity, and resistance to abrasion. Consistency in thread quality is crucial, as any defect could compromise the rope's performance and safety.

3. Core Construction (Kern)

The kern (core) is the primary load-bearing part of the rope. It is made by twisting and braiding multiple threads into a central bundle. This bundle is designed to provide maximum tensile strength and elasticity. The structure of the kern varies depending on whether the rope is intended to be static or dynamic.

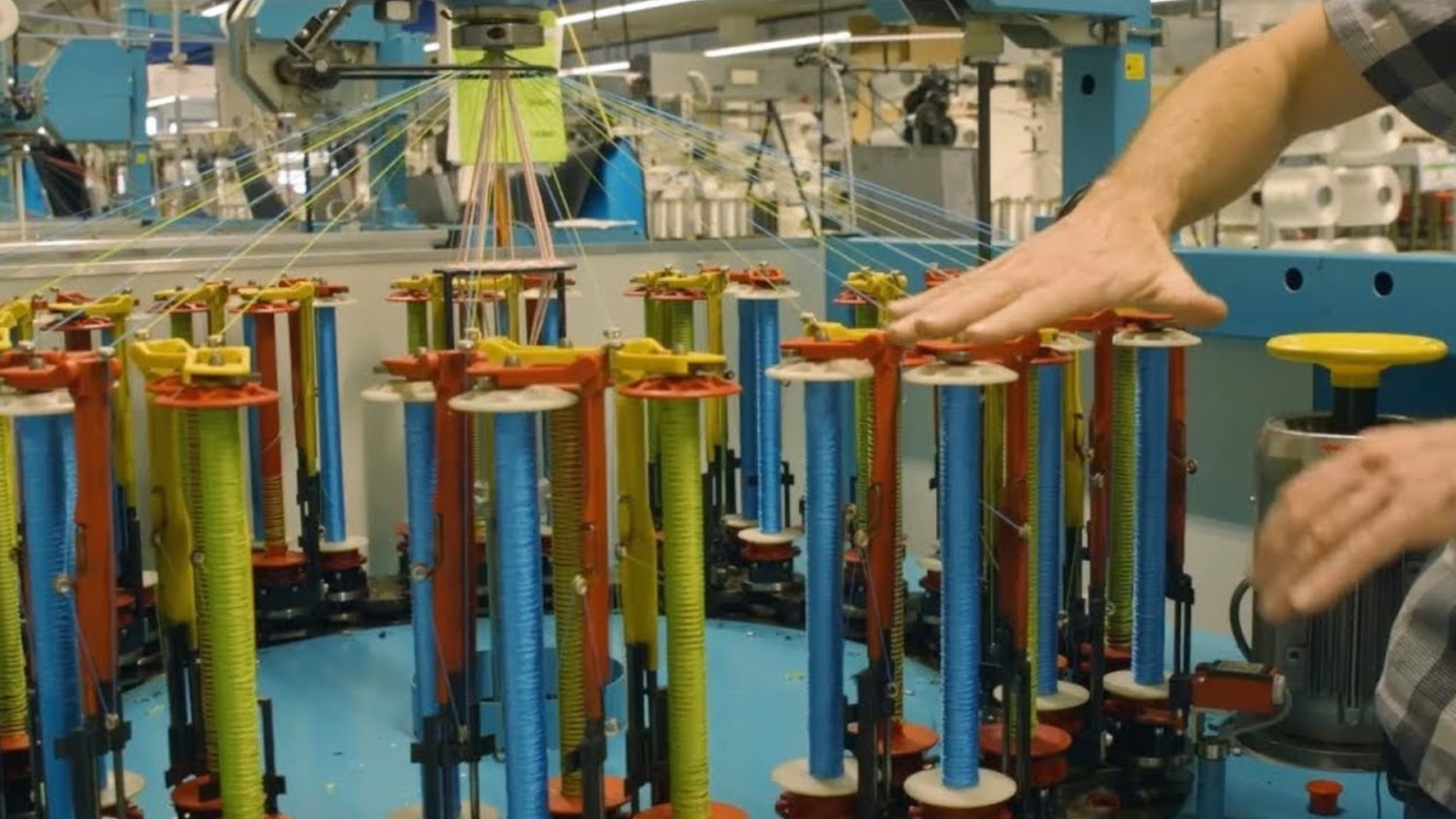

4. Sheath Braiding (Mantle)

The mantle (sheath) is braided around the core to provide durability, protect against abrasion, and enhance the rope's handling characteristics. The sheath is woven tightly to create a smooth, consistent surface that resists fraying and protects the inner core. The number of strands and the type of braiding used can affect the rope's feel and grip.

5. Heat Treatment and Bonding

Once the core and sheath are combined, the rope undergoes a heat treatment process. This step bonds the core and sheath together, improving the rope's overall strength and reducing the likelihood of slippage between the layers.

6. Dyeing and Coating

The ropes are dyed in vibrant colors for visibility and easy identification. Some manufacturers also apply specialized coatings to improve water resistance, UV protection, or abrasion resistance. This step ensures that the ropes can perform reliably in various environmental conditions.

7. Quality Control and Testing

Before reaching the market, climbing ropes undergo rigorous testing to ensure they meet safety standards such as those set by the UIAA (International Climbing and Mountaineering Federation) and CE (European Conformity). Tests include:

- Tensile strength tests to measure the rope's breaking load.

- Impact force tests to assess the rope's ability to absorb shock.

- Abrasion tests to evaluate durability against rough surfaces.

Each rope is inspected for consistency, and samples are subjected to extreme stress testing to ensure safety and reliability.

8. Cutting and Finishing

After passing quality control, the ropes are cut to specific lengths and finished with sealed ends to prevent fraying. Customizations, such as adding markers for middle points or attaching tags with safety information, are also completed at this stage.

9. Packaging and Distribution

Finally, the ropes are packaged with detailed user instructions and safety guidelines. As a trusted climbing rope manufacturer, we ensure ropes are shipped efficiently through our climbing rope wholesale and climbing rope distributor channels, catering to global markets.