Innovative Carabiner Solutions: Redefining Climbing Adventures

As leaders in the climbing gear industry, we proudly introduce our advanced line of Locking Carabiners, where safety, innovation, and reliability converge to redefine your climbing adventures. Our premium collection, designed by a leading locking carabiner manufacturer, is meticulously crafted to be your secure link during every ascent, delivering unparalleled security for climbers ranging from enthusiasts to seasoned professionals.

The Basics of Climbing Carabiners

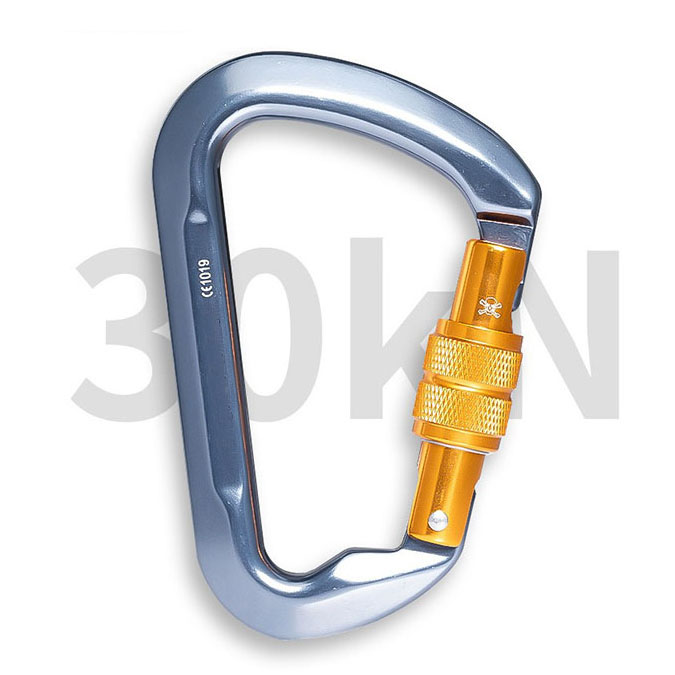

A climbing carabiner is a specialized piece of hardware used to connect various components of a climbing system, such as ropes, harnesses, and belay devices. Its primary function is to securely attach these components while allowing for quick and easy manipulation when needed. When choosing a climbing carabiner, consider key features such as high strength ratings and the type of gate mechanism. Our innovative Elastic Auto Locking carabiner, available through our locking carabiner wholesale and locking carabiner distributor network, automatically locks when closed for added security.

Auto-Locking Mechanism for Unwavering Security

Our Locking Carabiner boasts an auto-locking mechanism that ensures unwavering security. This innovative feature automatically engages when the gate is closed, minimizing the risk of accidental openings. The Elastic Auto-Locking carabiner, a product of our cutting-edge locking carabiner factory, represents a paradigm shift in climbing safety with its precision-engineered auto-locking mechanism. This makes it one of the best locking carabiners for belaying and climbing.

Anchor Building Precision in Multi Shapes

Precision is key when building anchors. Our compact Locking Carabiner, supplied by trusted locking carabiner agents, allows for precise configurations, blending style and functionality. Crafted with a distinctive shape and advanced locking mechanism, this carabiner not only ensures safety but also adds sophistication to your climbing gear. Whether you prefer a screw gate, twist lock, or the advanced Elastic Auto Locking system, our carabiners cater to all your climbing needs, making them the best locking carabiners for climbing.

Keylock Nose to Prevent Snagging

Climbing should be smooth, without the hassle of snagged gear. Our carabiner incorporates a keylock nose design, preventing snags during clipping and unclipping. Constructed from high-quality materials and featuring a robust locking system, this carabiner, available for locking carabiner sale, ensures efficient and hassle-free operation.

Certified Safety and Durability

In professional climbing settings, adherence to safety standards is paramount. Our climbing carabiners meet industry certifications such as UIAA and CE, undergoing rigorous testing to ensure performance and reliability. By using certified climbing carabiners from a reputable locking carabiner supplier, climbers can mitigate risks and comply with regulatory requirements, demonstrating a commitment to safety and responsible climbing practices.

Proper Care and Maintenance

To ensure the longevity and reliability of your climbing carabiners, proper care and maintenance are essential. Regularly inspect your carabiners for signs of wear and replace any damaged equipment immediately. Clean your carabiners with mild soap and water, and store them in a dry, well-ventilated area to prevent corrosion. Our locking carabiner factory provides guidelines to help you maintain your equipment in top condition.

Our premium collection of Locking Carabiners, available through our extensive network of locking carabiner wholesale, agents, and distributors, redefines safety and reliability in climbing gear. By investing in high-quality, certified carabiners, climbers can enjoy their adventures with confidence, knowing they are protected by the best equipment available. Explore our range today and take advantage of our locking carabiner sale to gear up for your next climbing expedition with the best in the industry.

FAQs section addressing common questions about How Are Carabiners Made?

A Detailed Look at the Manufacturing Process

Carabiners, essential tools in various outdoor and industrial activities, undergo a meticulous manufacturing process to ensure durability, strength, and reliability. Understanding how carabiners are made can provide insight into their performance. Here’s a detailed look into the steps involved in the production of carabiners, particularly focusing on the role of a locking carabiner factory.

- Material Selection

The journey of a carabiner begins with selecting high-quality materials. Most carabiners are made from aluminum alloy, renowned for its lightweight properties and excellent strength-to-weight ratio. Some specialized models may utilize steel or titanium for enhanced durability in extreme conditions. This critical step ensures the final product can withstand the demands of climbing and other activities.

- Forging

Forging is a pivotal step in manufacturing. At the locking carabiner factory, aluminum alloy blanks, known as billets, are heated to temperatures exceeding 700°C (1292°F) to make them malleable. These billets are then placed in a forging press, where immense pressure shapes them into the iconic carabiner form. This process imparts strength to the metal and allows for intricate designs to be incorporated.

- CNC Machining

Once forged, the rough carabiner blanks undergo precision machining to refine their shape and dimensions. Computer-controlled lathes and milling machines cut threads, drill holes, and add grooves or notches. This stage also includes adding gate mechanisms, such as wire gates, screw gates, or auto-locking mechanisms, which are crucial for the carabiner's functionality and safety.

- Heat Treatment

To enhance strength and durability, the machined carabiners undergo a heat treatment process. This involves controlled heating and cooling cycles, known as annealing and quenching. These thermal treatments relieve internal stresses in the metal and refine its grain structure, resulting in a stronger and more resilient final product.

- Surface Treatment

To protect the carabiner from corrosion and wear, surface treatments are applied. Common methods include:

Anodizing: An electrochemical process forming a durable oxide layer on the surface of aluminum carabiners. This layer can be dyed various colors for aesthetic purposes.

Galvanizing: Applying a protective zinc coating to steel carabiners to prevent rust.

- Assembly

The carabiner’s gate mechanism is assembled in this step. The gate, typically made from a separate piece of metal or wire, is attached to the carabiner body using a hinge pin. Key components include:

Spring: Ensures the gate automatically closes after opening.

Locking Mechanism: In locking carabiners, a sleeve or twist-lock mechanism is added to prevent accidental opening.

- Quality Control

Before being released to locking carabiner wholesale and locking carabiner distributor networks, every carabiner undergoes rigorous quality control measures and testing procedures. This includes visual inspections for defects, as well as mechanical testing to verify load-bearing capacity and gate strength. Only carabiners that meet or exceed industry standards are deemed fit for distribution.

- Certification

Finally, carabiners are certified according to industry standards, such as those set by the UIAA (International Climbing and Mountaineering Federation) or CE (Conformité Européenne). These certifications confirm that the carabiners meet rigorous safety requirements.

The production of carabiners is a complex and highly regulated process that combines precision engineering with metallurgical expertise. From material selection to hot forging, machining, heat treatment, and rigorous testing, each step plays a crucial role in ensuring the quality and performance of these essential climbing and safety tools. Locking carabiner manufacturers, suppliers, and wholesalers collaborate to bring these meticulously crafted carabiners to market, ensuring climbers and outdoor enthusiasts have access to reliable gear at competitive prices. Understanding this process highlights the importance of quality and precision in producing these essential pieces of equipment.