The Production of Climbing Helmets

What is a Climbing Helmet?

A mountain climbing helmet, also known as a climbing safety helmet, is a specialized piece of protective gear designed to safeguard the climber’s head during climbing activities. It is engineered to absorb impact and distribute force to minimize the risk of serious injury.

Key Features of Climbing Helmets:

-

Impact Resistance: Protects against falling debris and accidental head bumps.

-

Lightweight Design: Ensures comfort during prolonged use.

-

Ventilation: Keeps climbers cool during intense physical activity.

-

Adjustability: Provides a secure fit for various head sizes and shapes.

Different Materials of Climbing Helmets

The materials used in mountaineering helmets play a crucial role in their safety, durability, and weight. Different types of helmets are crafted using a combination of materials to achieve specific performance characteristics.

1. Polycarbonate (PC) Shells

-

Advantages: Lightweight, durable, and resistant to cracking.

-

Use Case: Common in recreational climbing helmets for indoor and outdoor activities.

2. Acrylonitrile Butadiene Styrene (ABS)

-

Advantages: Offers high-impact resistance and affordability.

-

Use Case: Often used in entry-level types of climbing helmets.

3. Expanded Polystyrene (EPS) Foam

-

Advantages: Excellent shock absorption and energy dissipation.

-

Use Case: Found in high-performance helmets, paired with a hard outer shell.

4. Carbon Fiber

-

Advantages: Lightweight, extremely durable, and premium in quality.

-

Use Case: Used in carbon fiber climbing helmets for professional climbers seeking top-tier protection.

5. Hybrid Combinations

-

Advantages: Combines materials like polycarbonate and EPS foam for optimized performance.

-

Use Case: Used in advanced climbing helmets to balance weight, durability, and safety.

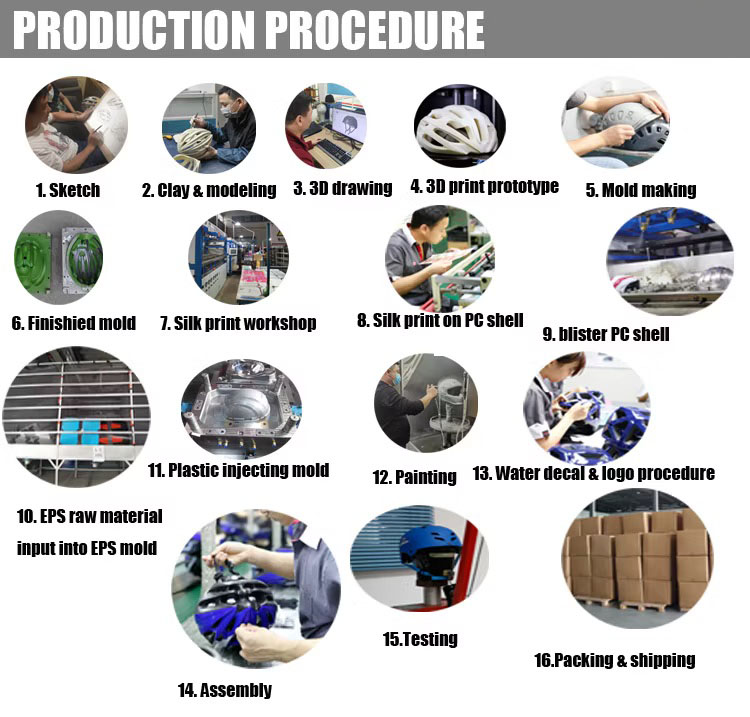

The Manufacturing Process of a Climbing Helmet

The production of a climbing helmet involves multiple stages, combining advanced technology and precision engineering. Here is a step-by-step overview:

1. Design and Prototyping

-

Initial Concepts: Helmet manufacturers design helmets using CAD (Computer-Aided Design) software to create 3D models.

-

Prototyping: Initial prototypes are crafted to test functionality, fit, and aesthetics.

2. Material Selection

-

Choosing Materials: Based on the type of climbing helmet, manufacturers select appropriate materials such as polycarbonate, ABS, or carbon fiber.

-

Supplier Coordination: Collaboration with reliable helmet suppliers ensures the consistent quality of raw materials.

3. Shell Formation

-

Injection Molding: For polycarbonate or ABS shells, injection molding is used to create the outer layer.

-

Hand-Laying: Carbon fiber shells are often hand-laid for precision and strength.

4. Foam Molding

-

EPS Foam Creation: Expanded Polystyrene foam is molded to fit the inner contour of the helmet. It acts as a cushion during impacts.

5. Assembly

-

Combining Components: The outer shell and inner foam are bonded together using advanced adhesives or mechanical locking systems.

-

Straps and Adjustments: Chin straps, padding, and adjustment mechanisms are attached for functionality and comfort.

6. Quality Control

-

Impact Testing: Each helmet undergoes rigorous safety testing to meet industry standards.

-

Inspections: Helmets are inspected for structural integrity, fit, and finish.

7. Branding and Packaging

-

Customization: Helmets can be customized with logos or colors, especially for bulk orders through helmet distributors or helmet wholesale channels.

-

Packaging: Eco-friendly packaging ensures helmets are protected during shipping.

Why Choose a Reliable Helmet Manufacturer?

Working with a reputable helmet factory or helmet manufacturer ensures you receive high-quality helmets that meet safety certifications. Reliable suppliers often offer:

-

Bulk Discounts: Ideal for businesses purchasing through helmet wholesale channels.

-

Customization Options: Tailored designs to suit specific branding needs.

-

Consistent Quality: Adherence to strict manufacturing standards.

The production of climbing helmets is a sophisticated process that blends innovative design, high-performance materials, and stringent quality controls. Whether it’s a carbon fiber climbing helmet for professional use or a budget-friendly option for beginners, every helmet is crafted with safety and functionality in mind. For businesses, partnering with us, as trusted helmet distributor or helmet factory ensures access to premium products that climbers can rely on. Choose wisely and climb with confidence, knowing your head is well-protected.